Fish sauce is produced in most Asian countries (Park et al., 2001). Each country has its own unique taste of fish source depending on the nutritional value and sensory quality. Manufacturing methods are often standardized within regions or villages, but they are varying due to local customs and fish species used. There are many different names for fish sauce in Southeast Asia such as Bubu (Malaysia), nam-pla, Kapi (Thailand), nuoc-mam (Vietnam), Ngam-pya-ye (Myanmar), Patis (Philippines), Padec (Laos), Shotturu (Japan), traces (Indonesia) (FAO and WHO, 2007). In general, fish is washed, mixed with salt following a ratio ranging from 2:1 to 3:1, and fermented at room temperature for 5 - 24 months depending on the production area (Lopetcharat et al., 2015; Park et al., 2001). Fukami et al. (2002) reported that fish sauce is basically produced from a mixture of fish and salt (3:1) that has been allowed to ferment for a period of up 6 months at a temperature of 30 - 35 °C. Although the high salty concentration is a potential condition for the inhibition of hydrolytic activity and the commercial supplement enzyme activity, it is needed to prevent deterioration from the mixture of fermented fish (Aspmo et al., 2005). The manufacturing process of fish sauce can be shortened by promoting fish hydrolysis from external protease sources such as papain, bromelain (Beddows and Ardeshir, 1979), or microorganisms such as Bacillus licheniformis RKK-04 (Toyokawa et al., 2010), Tetragenococcus halophilus (Udomsil et al., 2011), Staphylococcus carnosus and Bacillus amyloliquefaciens (Zaman et al., 2011). It was reported that spleen proteinase (spleen of Skipjack tuna) is also a potential novel enzyme for the acceleration of fish sauce production (Zaman et al., 2011). Youngsawatdigul et al. (2007) reported that the addition of starter culture reduced the fermentation time by 40%. Gupta et al. (2002) suggested that the proteases from microbial sources are preferred than from plant or animal sources, as they can meet the increasing demand and possess almost all the characteristics desired for various biotechnology industries. Ooshiro et al. (1981) reported that the commercial enzyme of papain increased the fermentation rate of fish sauce at various operating conditions and gave high contents of total soluble nitrogen, amino-type nitrogen, and volatile base nitrogen. However, it still remains unclear whether the commercial enzymes might influence the degree of hydrolysis during the fish fermentation time. Taking these into account, Chau et al investigated the effect of the Protex 51FP enzyme on the degree of hydrolysis during the fish sauce fermentation time and the sensory and nutritional quality of fish sauce products.

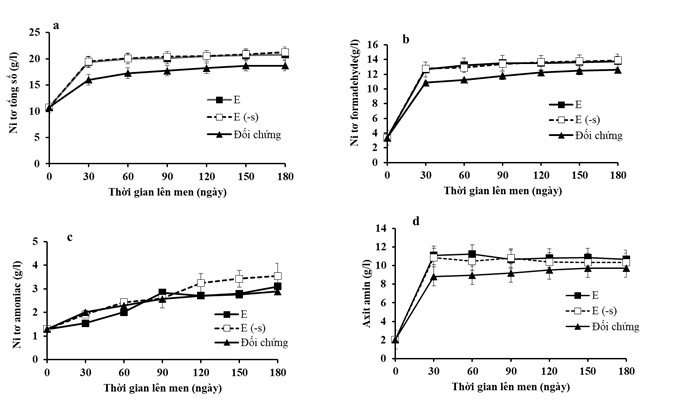

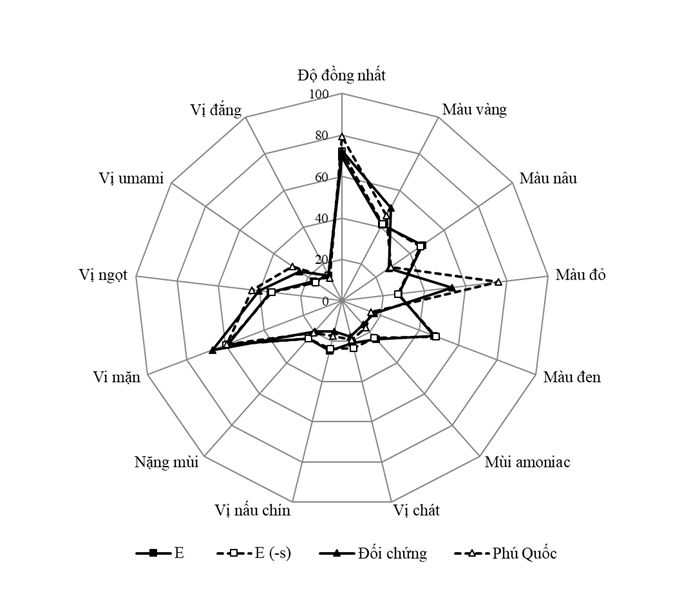

In this 180-day study, commercial Protex 51FP enzyme effects as a starter culture on anchovy fish sauce fermentation were investigated. Three fish source fermentation groups, including a control group (the anchovy with 25% of salt addition), E group (the anchovy with 25% of salt and 1% of Protex 51FP addition), and E (-s) group (the anchovy with 1% of Protex 51FP and after 6 hours with 25% of salt), were compared. The fish sauce fermentation groups were sampled, packed into glass jars (10 liters), and covered by a lid at ambient temperature (22 - 30°C) for 180 days. Three commercial fish sauces were also included as nutritional references. The results showed that the addition of Protex 51FP achieved positive results of total nitrogen content and amino acids compared to the control samples (p<0.05). These values were competitive with commercial product figures. Total amino acids in 8000mg/100ml fish sauce were significantly higher than those in the control (Figure 1). There were rich in essential amino acids (41-43%) and small peptides (13% peptides with a molecular weight below 200 Da, 32-39% peptides with a molecular weight below 130 - 200 Da, and 25-28% of peptides with a molecular weight below 200 – 360 Da). Compared with traditional methods, the addition of Protex 51FP (p<0.05) could improve the quality of fish sauce and obtain greater nutritional values. In all experiments, the color of adding-enzyme samples was darker than that of the traditional products, and the smell of these samples (including traditional methods) was not as quite strong as commercial products.

|

|

| Fig 1: The values of total nitrogen (a), formaldehyde nitrogen (b), ammonia nitrogen (c) and amino nitrogen (d) in the fermentation process of fish sauce. Data as mean ± SD. |

|

|

| Fig 2: Star diagrams of sensory properties of fish sauces obtained from experiment and the commercial |

References

Aspmo, S. I., S. J. Horn and V. G. H. Eijsink. 2005. Enzymatic hydrolysis of Atlantic cod (Gadus morhua L.) viscera. Process Biochem. 40 (5): 1957-1966.

Beddows, C. G. and A. G. Ardeshir. 1979. The production of soluble fish protein solution for use in fish sauce manufacture. J. Food Sci. Technol. 14 (6): 603-612.

Fukami, K., S. Ishiyama, H. Yaguramaki, T. Masuzawa, Y. Nabeta, K. Endo and M. Shimoda. 2002. Identification of distinctive volatile compounds in fish sauce. J. Agric. Food Chem. 50 (19): 5412-5416.

FAO and WHO. 2007. Codex Alimentarius Commission CX/FFP 08/29/9. Joint FAO/WHO food standards programme. Codex committee on fish and fishery products.

Lopetcharat, K., Y. J. Choi, J. W. Park, M. A.Daeschel, Y. J. Choi, J. W. Park, M. A. Daeschel, K. Lopetcharat, Y. J. Choi and J. W. Park. 2015. Fish sauce products and manufacturing: a review. Food Rev. Int. 9129 (10): 37-41.

Lopetcharat, K. and J. W. Park. 2002. Characteristics of fish sauce made from pacific whiting and surimi by-products during fermentation stage. J. Food Sci. 67 (2): 511-516.

Park, J. N., Y. Fukumoto, E. Fujita, T. Tanaka, T. Washio, S. Otsuka, T. Shimizu, K. Watanabe and H. Abe. 2001. Chemical composition of fish sauces produced in Southeast and East Asian countries. J Food Compost Anal. 14 (2): 113-125.

Toyokawa, Y., H. Takahara, A. Reungsang, M. Fukuta, Y. Hachimine, S. Tachibana and M. Yasuda. 2010. Purification and characterization of a halotolerant serine proteinase from thermotolerant Bacillus licheniformis RKK-04 isolated from Thai fish sauce. Appl. Microbiol. Biotechnol. 86 (6): 1867-1875.

Udomsil, N., S. Rodtong, Y.J. Choi, Y. Hua and J. Yongsawatdigul. 2011. Use of tetragenococcus halophilus as a starter culture for flavor improvement in fish sauce fermentation. J. Agric. Food Chem. 59 (15): 8401-8408.

Yoshikawa, M., H. Fujita, N. Matoba, Y. Takenaka. 2000. Bioactive peptides derived from food proteins preventing lifestyle-related diseases. BioFactors 12: 143-146.

Chau, L.M., Ngoc, H.T.B., Donnay-Moreno, C., Bruzac, S., Berge, J.P., Hanh, V.T. 2021. Protex 51FP as a starter for accelerating fish sauce fermentation from anchovy (Stolephorus commersonii). Emir J Food Agric. 33(5): 379-387.

Vu Thi Hanh, Faculty of Food Science and Technology